Ezweni elihlala livela lokukhiqiza, izingxenye zemishini ye-CNC eziguqukayo zihola uguquko. Njengoba izimboni zifuna ukunemba okukhulu, ukusebenza kahle, nokwenza ngendlela oyifisayo, ubuchwepheshe be-CNC (Computer Numerical Control) buye baba baluleke kakhulu, ikakhulukazi ekuguquleni imisebenzi. Lezi zingxenye eziklanywe ngobunyoninco zinika amandla yonke into kusukela ezinjinini zezimoto kuya ezingxenyeni ze-aerospace, okwenza ukuguqula izingxenye zemishini ye-CNC zibe itshe lesisekelo lenqubekelaphambili yesimanje yezimboni.

Kodwa kungani lezi zingxenye zibaluleke kangaka, futhi zikuchaza kanjani kabusha ukukhiqiza? Ake sihlole ukuthi ukuguqula imishini ye-CNC kusetha kanjani amabhentshimakhi amasha wokunemba, ukusebenza, nokusebenza kahle kokukhiqiza.

Yiziphi Izingxenye Zomshini ze-CNC?

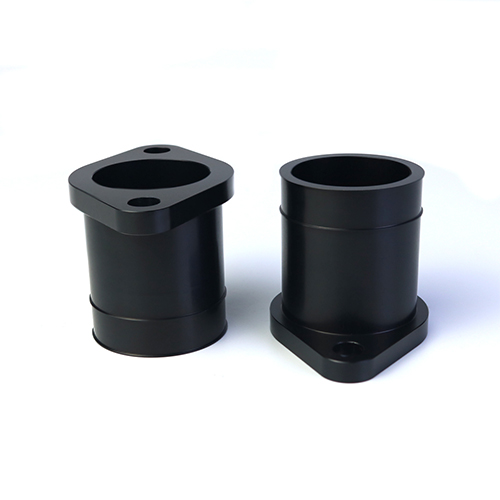

Emgogodleni wayo, ukuguqula imishini ye-CNC kuhilela ukususa impahla kucezu lokusebenza oluzungezayo ukuze kwakheke umumo oyisilinda onembile. Le nqubo yenziwa kusetshenziswa amalebula e-CNC athuthuke kakhulu, ahlelelwe ukukhiqiza izingxenye ngokunemba okukhethekile nokungaguquguquki.

Izibonelo ezijwayelekile zokuphendulela izingxenye zemishini ye-CNC zifaka imiphini, amahlahla, ama-spindle, izikulufu, nama-flange, konke okudinga ukunemba okuphezulu ukuze kuqinisekiswe ukusebenza okungenazihibe ezinhlelweni zakho zokusebenza ngokulandelana kwazo.

Ngokungafani nezindlela zokuguqula ezivamile, imishini ye-CNC ingakhiqiza izingxenye ezinokubekezelelana kwezinga le-micron, izenze zifaneleke ezimbonini lapho ukuchezuka okuncane kakhulu kungafaka engcupheni ukusebenza, okufana ne-aerospace, izinto zezokwelapha, ezezimoto, nezinto zikagesi.

Kungani Ukuguqula Izingxenye Zemishini Ye-CNC Ziguqule

1. Ukunemba Okungenakuqhathaniswa

Ukunemba kuwuphawu lokuguqula imishini ye-CNC. Amalebula esimanje e-CNC afakwe isoftware esezingeni eliphezulu namathuluzi avumela abakhiqizi ukuthi bakhiqize izingxenye ngokunemba okumangalisayo.

Isibonelo, izingxenye ze-aerospace ezifana nama-turbine shafts noma izifakelo zezokwelapha njengezikulufu zethambo zidinga i-geometry ephelele ukuze isebenze njengoba kuhlosiwe. Ukuguqulwa kwe-CNC kuqinisekisa ukuthi lezi zingxenye zihlangabezana nezindinganiso eziqinile zekhwalithi, zisusa ubungozi obuhambisana namaphutha enziwa ngesandla.

2. Ukwenyuka Kwempumelelo Yokukhiqiza

Imishini yokuguqula i-CNC isebenza ngesivinini esikhulu ngenkathi igcina ukuvumelana kuwo wonke ama-run okukhiqiza amakhulu. Ngokungafani namalebula okwenziwa ngesandla, adinga ukugadwa umuntu njalo, amalebula e-CNC angasebenza ngokuzenzakalelayo, anciphise ngokuphawulekayo isikhathi sokukhiqiza nezindleko zabasebenzi.

Ezimbonini ezikhiqiza izingxenye ezinkulu zezingxenye eziphendukile, njengemishini yezimoto noma yezimboni, ubuchwepheshe be-CNC buvumela ukukhiqiza okusheshayo, okungabizi kakhulu ngaphandle kokudela ikhwalithi.

3. Ukwenza Ngokwezifiso Okuthuthukisiwe

Ukuvumelana nezimo komshini we-CNC kuvumela abakhiqizi ukuthi bakhiqize izingxenye zangokwezifiso eziklanyelwe izinhlelo zokusebenza ezithile. Ngesofthiwe ethuthukisiwe ye-CAD/CAM, onjiniyela bangaklama amajiyometri ayinkimbinkimbi futhi bawahumushele ezinhlelweni ze-CNC.

Kungakhathaliseki ukuthi iyisibonelo esisodwa noma iqoqo lezingxenye zangokwezifiso zezinjini ezisebenza kahle kakhulu, ukuguqulwa kwe-CNC kunikeza inkululeko yokuklama engenakuqhathaniswa. Lokhu kubaluleke kakhulu emikhakheni efana nemidlalo yezimoto kanye nezimpahla zikanokusho, lapho izingxenye ezihlukile, ezisebenza kahle zidingeka kakhulu.

4. Superior Material Compatibility

Imishini yokuguqula i-CNC ingakwazi ukuphatha izinto eziningi ezihlukahlukene, kusukela ezinsimbi zendabuko njenge-aluminium, insimbi, nethusi, kuya kuma-alloys athuthukile nezinhlanganisela ezifana ne-titanium ne-carbon fiber.

Lokhu kuguquguquka kwenza abakhiqizi bakwazi ukuhlangabezana nezidingo ezihlukene zezimboni ezidinga izinto ezinezici ezithile, njengezingxenye ze-aerospace ezingasindi noma izigxivizo zezokwelapha ezimelana nokugqwala.

Izicelo Zokushayela Isidingo Sokuguqula Izingxenye Zomshini ze-CNC

1.Imboni Yezimoto

Izingxenye zomshini ze-CNC ezishintshayo zibalulekile emkhakheni wezimoto, zikhiqiza izingxenye ezibalulekile njengamaphistola enjini, izinsimbi zamagiya, nezinto zokuqondisa. Ukunemba nokuqina kwezingxenye eziphendulwe yi-CNC kuqinisekisa ukusebenza kahle kwemoto, ukusebenza kahle, nokuphepha.

2.Ubunjiniyela be-Aerospace

Emkhathini, asikho isikhala sephutha. Izingxenye eziphendulwe yi-CNC njengezibophelelo zendiza, izingxenye zegiya lokuhlala, kanye namashafu ophephela akhiwe ngendlela enembile ukuze kuhlangatshezwane nezidingo ezinzima zezindawo zendiza.

3.Amadivayisi Ezokwelapha

Imboni yezokwelapha ithembele kakhulu emishinini ye-CNC ukuze ikhiqize amathuluzi okuhlinza, izimila, nezitho zokufakelwa. Ukuvula imishini ye-CNC kuqinisekisa ukuthi lezi zingxenye azinembi nje kuphela kodwa futhi ziyahambelana ne-biocompatible futhi ziphephile ukusetshenziswa ezinhlelweni ezibucayi.

4.Ezogesi

Kusukela kwizixhumi ezincane kuya kumasinki okushisa, ukuphenduka kwe-CNC kudlala indima ebalulekile embonini yezogesi. Amandla okusebenza ngezinto ezintekenteke nokukhiqiza izingxenye ezincane, eziyinkimbinkimbi lenze ukuguqulwa kwe-CNC kwaba semqoka kulo mkhakha.

Intuthuko Yezobuchwepheshe ku-CNC Turning

Umkhakha we-CNC turning uthuthuka ngokushesha, ngezinto ezintsha ezithuthukisa isivinini, ukunemba, nokusebenza:

1. Multi-Axis CNC Lathes

Amalebula esimanje e-CNC manje afaka amakhono e-multi-eksisi, avumela amajiyometri ayinkimbinkimbi ukuthi akhiqizwe ngokusetha okukodwa. Lokhu kuqeda isidingo sokusebenza kwesibili, kunciphisa isikhathi sokukhiqiza nezindleko.

2. Ukuhlanganiswa kwe-IoT

Imishini ye-Smart CNC efakwe izinzwa ze-IoT ivumela ukuqapha kwesikhathi sangempela kokusebenza kwemishini, iqinisekisa ukulawulwa kwekhwalithi nokugcinwa kokubikezela.

3. Amathuluzi Okusika Athuthukile

Ukuthuthukiswa kwamathuluzi okusika asebenza kahle kakhulu, afana nokufakwa kwe-carbide okunesihloko sedayimane noma okunamathiselwe, kuthuthukise ukusebenza kahle kwemishini kanye nempilo yamathuluzi eyandisiwe, ngisho nalapho isebenza ngezinto eziqinile njenge-titanium noma i-Inconel.

Ikusasa Lokuguqula Izingxenye Zomshini ze-CNC

Njengoba izimboni ziqhubeka nokufuna ukunemba okuphezulu nokusebenza kahle, ukuguqula imishini ye-CNC kuzodlala indima ebaluleke kakhulu. Ukuhlanganiswa kobuhlakani bokwenziwa kanye ne-automation ilungele ukwenza imishini yokuphendula ye-CNC ihlakaniphe nakakhulu futhi ikwazi, okuvumela ukwenziwa ngokwezifiso okukhulu nemijikelezo yokukhiqiza esheshayo.

Ngaphezu kwalokho, ngokuphokophela ukusimama, ukwenziwa kwemishini ye-CNC kusebenzisa imikhuba eco-friendly, njengokunciphisa udoti wezinto ezibonakalayo ngokusebenzisa izinqubo zokumachine ezithuthukisiwe kanye nokusebenzisa izinto ezigaywa kabusha.

Isiphetho: Ukuguqula Izingxenye Zomshini ze-CNC Njengesisusa Senqubekelaphambili

Ukwenyuka kwezingxenye zomshini ze-CNC eziguqukayo kumelela ukweqa okubalulekile ezimbonini zokukhiqiza. Ngokuhlanganisa ukunemba, ukusebenza kahle, nokuguquguquka, lezi zingxenye zishayela ukuqamba okusha kuzo zonke izinhlobo zezinhlelo zokusebenza, kusukela kwezokuthutha nokunakekelwa kwezempilo kuye kwezobuchwepheshe nokuvikela.

Njengoba ubuchwepheshe be-CNC buqhubeka nokuthuthuka, amathuba okuguqula izingxenye zemishini ye-CNC awanamkhawulo. Kubakhiqizi abahlose ukuhlala bencintisana emhlabeni oshintsha ngokushesha, ukutshala imali emandleni okuguqula i-CNC akuyona nje inketho—kuyisidingo.

Noma ngabe inika amandla izimoto zesizukulwane esilandelayo, inika amandla izisetshenziswa zezokwelapha ezisindisa impilo, noma ukudala izinto zikagesi zesikhathi esizayo, izingxenye zomshini we-CNC ezishintshayo zihamba phambili ekukhiqizeni okunembayo ekhulwini lama-21.

Isikhathi sokuthumela: Jan-06-2025