PFT, Shenzhen

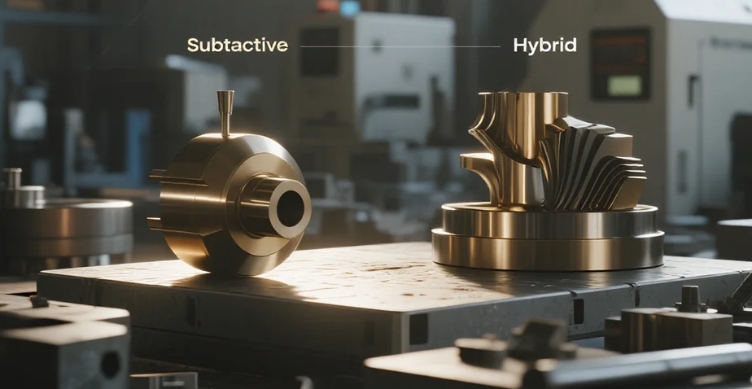

Lolu cwaningo luqhathanisa ukusebenza kahle kwemishini ye-CNC yendabuko ekhiphayo nengxube ekhulayo ye-CNC-Additive Manufacturing (AM) yokulungisa amathuluzi ezimboni. Amamethrikhi okusebenza (isikhathi sokulungisa, ukusetshenziswa kwezinto ezibonakalayo, amandla okusebenza) alinganiswa kusetshenziswa ukuhlola okulawulwayo ekufakeni isitembu okonakele. Imiphumela ikhombisa izindlela ezixubile zehlisa udoti wezinto ezibonakalayo ngo-28–42% futhi zifinyeze imijikelezo yokulungisa ngo-15–30% uma kuqhathaniswa nezindlela zokususa kuphela. Ukuhlaziywa kwe-Microstructural kuqinisekisa amandla e-tensile aqhathaniswayo (≥98% wethuluzi langempela) ezingxenyeni ezilungiswe ngokuxubile. Umkhawulo oyinhloko ubandakanya izingqinamba eziyinkimbinkimbi zejiyomethri zokubekwa kwe-AM. Lokhu okutholakele kubonisa i-hybrid CNC-AM njengesu elisebenzayo lokugcinwa kwamathuluzi esimeme.

1 Isingeniso

Ukucekelwa phansi kwamathuluzi kubiza izimboni zokukhiqiza u-$240B ngonyaka (NIST, 2024). Ukulungisa okujwayelekile kwe-CNC okukhiphayo kususa izingxenye ezilimele ngokugaya/ukugaya, ngokuvamile kulahla >60% wezinto ezingahlengwa. Ukuhlanganiswa kwe-Hybrid CNC-AM (ukufakwa kwamandla okuqondile kumathuluzi akhona) kuthembisa ukusebenza kahle kwensiza kodwa akunakho ukuqinisekiswa kwezimboni. Lolu cwaningo lulinganisa izinzuzo zokusebenza zokugeleza komsebenzi okuxubile kuqhathaniswa nezindlela ezivamile zokususa zokulungiswa kwamathuluzi anenani eliphezulu.

2 Indlela

2.1 Idizayini Yokuhlola

Izitembu eziyisihlanu ezilimele ze-H13 zensimbi ziyafa (ubukhulu: 300 × 150 × 80mm) zenze imigomo emibili yokulungisa:

-

Iqembu A (Okukhiphayo):

- Ukususwa komonakalo nge-5-axis milling (DMG MORI DMU 80)

- Ukufakwa kwe-Welding filler (GTAW)

- Qedela ukwenza imishini ku-CAD yasekuqaleni -

Iqembu B (IHybrid):

- Ukususwa kwesici esincane (<1mm ukujula)

- Ukulungiswa kwe-DED kusetshenziswa i-Meltio M450 (316L wire)

- I-Adaptive CNC remachining (Siemens NX CAM)

2.2 Ukutholwa Kwedatha

-

Ukusebenza Kwezinto Ezibalulekile: Izilinganiso ezinkulu ngaphambi/ngemuva kokulungiswa (Mettler XS205)

-

Ukulandelela Isikhathi: Ukuqapha inqubo ngezinzwa ze-IoT (ToolConnect)

-

Ukuhlolwa Komshini:

- Ukuqina kwemephu (Buehler IndentaMet 1100)

- Amasampula e-Tensile (ASTM E8/E8M) asuka ezindaweni ezilungisiwe

3 Imiphumela & Ukuhlaziya

3.1 Ukusetshenziswa Kwezinsiza

Ithebula 1: Ukuqhathanisa Kwenqubo Yokulungisa Amamethrikhi

| Imethrikhi | Ukulungisa Okususayo | Ukulungisa Ingxubevange | Ukuncishiswa |

|---|---|---|---|

| Ukusetshenziswa Kwempahla | 1,850g ± 120g | 1,080g ± 90g | 41.6% |

| Isikhathi Sokulungisa Esisebenzayo | 14.2 ihora ± 1.1 ihora | 10.1 ihora ± 0.8 amahora | 28.9% |

| Ukusetshenziswa kwamandla | 38.7 kWh ± 2.4 kWh | 29.5 kWh ± 1.9 kWh | 23.8% |

3.2 Ubuqotho Bemishini

Izibonelo ezilungiswe nge-Hybrid zibonisiwe:

-

Ukuqina okungaguquki (52–54 HRC vs. 53 HRC yasekuqaleni)

-

Amandla okuqina okugcina: 1,890 MPa (±25 MPa) - 98.4% wezinto eziyisisekelo

-

Akukho delamination phakathi kobuso ekuhlolweni kokukhathala (imijikelezo engu-10⁶ ku-80% wokucindezeleka kwesivuno)

Umfanekiso 1: I-Microstructure ye-hybrid yokulungisa isikhombimsebenzisi (SEM 500×)

Qaphela: Isakhiwo sokusanhlamvu esilinganayo emngceleni wokuhlanganisa sibonisa ukuphatha okushisayo okusebenzayo.

4 Ingxoxo

4.1 Imithelela yokusebenza

Ukwehliswa kwesikhathi ngo-28.9% kusuka ekususeni ukususwa kwezinto eziyinqwaba. Ukucubungula kwe-Hybrid kufakazela kunenzuzo ku:

-

Amathuluzi efa elinesitokwe sempahla esiyekiwe

-

Amajiyometri ayinkimbinkimbi (isb., amashaneli okupholisa ahlelekile)

-

Izimo zokulungisa ivolumu ephansi

4.2 Izingqinamba zobuchwepheshe

Imikhawulo iphawuliwe:

-

I-engeli enkulu yokubeka: 45° ukusuka evundlile (igwema ukonakala okungaphezulu)

-

Ukuhluka kogqinsi lwesendlalelo se-DED: ±0.12mm kudinga izindlela zamathuluzi eziguqukayo

-

Ukwelashwa kwe-HIP yangemva kwenqubo kubalulekile kumathuluzi ebanga le-aerospace

5 Isiphetho

I-Hybrid CNC-AM yehlisa ukusetshenziswa kwensiza yokulungisa amathuluzi ngo-23–42% kuyilapho igcina ukulingana komshini nezindlela zokususa. Ukusetshenziswa kunconyiwe ezingxenyeni ezinobunzima bejiyomethri emaphakathi lapho ukonga okubalulekile kuthethelela izindleko zokusebenza ze-AM. Ucwaningo olulandelayo luzothuthukisa amasu okufakwa kwezinsimbi zamathuluzi aqinile (>60 HRC).

Isikhathi sokuthumela: Aug-04-2025