Emhlabeni wezinga eliphezulu lokukhiqizwa kwamandla nemishini yezimboni, ukunemba nokusebenza kahle akuxoxiswana ngakho. Ukusetshenziswa kobuchwepheshe obusha emishinini yamasilinda e-turbine kuguqula inqubo yokukhiqiza, kunika amandla impumelelo ekusebenzeni, ukuqina, nokusimama. Ukusuka ekuphehleni ugesi kuye kwezokundiza, amasu emishini ethuthukisiwe achaza kabusha ukuthi amasilinda ophephela aklanywa, akhiqizwa, futhi anakekelwa kanjani.

Ukubaluleka kwe-Turbine Cylinder Machining

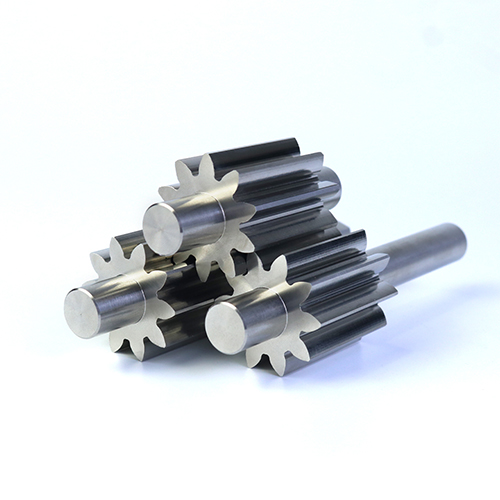

Amasilinda ohlobo lwe-turbine adlala indima ebalulekile ezinhlelweni ezifana nezinjini zesitimu, izinjini zegesi, kanye namajeneretha aphehla ugesi ngamanzi. Lezi zingxenye kufanele zibekezelele amazinga okushisa aphezulu, izingcindezi, nesivinini sokujikeleza. Ukufeza ukunemba okudingekayo ngesikhathi somshini kuqinisekisa:

●Ukusebenza Kahle:Ukunciphisa ukulahlekelwa kwamandla ngesikhathi sokusebenza.

●Ukuqina Okuthuthukisiwe:Ukwelula umjikelezo wempilo wezingxenye ze-turbine.

●Ukuphepha Okuthuthukisiwe:Ukunciphisa ubungozi obuhambisana nezindawo ezinengcindezi ephezulu.

Okusunguliwe Okubalulekile ku-Turbine Cylinder Machining

1.High-Precision CNC Machining

OkwesimanjeImishini ye-CNC (Computer Numerical Control).babeka izindinganiso ezintsha zokunemba ekukhiqizeni amasilinda e-turbine. Le mishini ivumela:

●Ukunemba Kwezinga Le-Micrometer:Ukuhlangabezana nokubekezelelana okuqinile okudingekayo ekusebenzeni kahle kwe-turbine.

●IJiyometri Eyinkimbinkimbi:Ivumela ukukhiqizwa kwemiklamo eyinkimbinkimbi ethuthukisa ukugeleza komoya nokudluliswa kokushisa.

● Udoti Owehlisiwe:Ukunciphisa ukumoshwa kwempahla ngokusebenzisa izindlela zokusika ezinembile.

1.Ukuhlanganiswa Kwezokukhiqiza Okungeziwe

Ukukhiqiza okungeziwe, noma ukuphrinta kwe-3D, kushintsha igeyimu ekufanekisweni nasekulungiseni kwesilinda se-turbine:

●I-Rapid Prototyping:Isheshisa ukuthuthukiswa kwemiklamo emisha ye-turbine.

●Ukuthuthukisa Okubalulekile:Ivumela izingxenye ezingasindi kodwa eziqinile.

●Ukulungiswa Kwendawo:Inika amandla ukubuyiselwa okunembile kwezindawo ezigugile noma ezilimele, inwebe impilo yesilinda.

1.I-Laser ne-Waterjet Cutting

Ubuchwepheshe bokusika obuthuthukisiwe njengezinhlelo ze-laser ne-waterjet zenza izinguquko ekubunjweni kokuqala kwamasilinda e-turbine:

●Ukusika Ongathintana Naye:Yehlisa ubungozi bokulimala okushisayo.

● Ukuhlukahluka:Iphatha inhlobonhlobo yezinto zokwakha, okuhlanganisa ama-superalloy avame ukusetshenziswa kuma-turbines.

●Imisebenzi Yejubane Eliphezulu:Inciphisa izikhathi zokukhiqiza ngenkathi igcina ikhwalithi.

1.I-Robotic Automation

Amasistimu wamarobhothi athuthukisa ukungaguquguquki nokusebenza kahle kumashini wamasilinda we-turbine:

●Izinguquko Zethuluzi Ezizenzakalelayo:Yehlisa isikhathi sokuphumula phakathi kwezinqubo zemishini.

●Ukuphatha Ngokunemba:Iqinisekisa ikhwalithi engaguquki kuyo yonke imisebenzi emikhulu yokukhiqiza.

● Ukuhlola Okunamandla E-AI:Ihlonza okungalungile ngesikhathi sangempela ukuze kulungiswe ngokushesha.

Izinzuzo Zobuchwepheshe obusha ku-Turbine Machining

●Imijikelezo Yokukhiqiza Esheshayo:Izinqubo ezintsha ezifana ne-CNC automation kanye nezinhlelo zamarobhothi zinciphisa kakhulu isikhathi somshini.

●Ukusebenza Kahle Kwezindleko:Izinqubo ezilungiselelwe zehlisa izindleko zokukhiqiza ngaphandle kokubeka engcupheni ikhwalithi.

●Ukusimama:Udoti wezinto ezincishisiwe kanye nemishini eyonga amandla isekela imigomo yemvelo.

●Ukusebenza Okuthuthukisiwe:Ukunemba kwemishini kuphumela kumasilinda e-turbine athuthukisa ukusebenza kahle nokuthembeka.

Izicelo Kuzo zonke Izimboni

●Ukukhiqiza Amandla:Amasilinda omoya ayizinhliziyo zezinjini zesitimu kanye negesi, ezibaluleke kakhulu ekukhiqizweni kukagesi. Ubuchwepheshe obusha buqinisekisa ukusebenza okungaguquki, ngisho nasezimisweni zamandla avuselelekayo njengezitshalo ze-geothermal.

● Umkhathi:Izinjini zezindiza zithembele ezingxenyeni ze-turbine ukuze zimelane nezimo ezimbi kakhulu. Ukwenza imishini ethuthukisiwe kwenza ukukhiqizwa kwezingxenye ezingasindi, ezinamandla amakhulu.

● Uwoyela Negesi:Ama-turbines asetshenziswa endaweni yokumba ogwini nasogwini azuza kumasilinda aqinile akhiwe ukuze abekezelele indawo enzima.

Elikuphethe Ikusasa

Ikusasa lomshini wamasilinda we-turbine lilele ekuhlanganisweni okuqhubekayo kokukhiqizwa okuhlakaniphile, lapho imishini enikwe amandla i-AI kanye ne-IoT izoshayela ukusebenza okuzimele. Izixazululo ze-Hybrid ezihlanganisa ukukhiqiza okukhiphayo kanye nokwengeza kuzonikeza ukuguquguquka okungenakuqhathaniswa, kuyilapho izinqubo ezizinzile zizohlala zibalulekile.

Isiphetho

Ukusetshenziswa kobuchwepheshe obusha kumashini womshini wamasilinda ophephela kuphawula isikhathi esibalulekile ezimbonini ezithembele kumaturbine. Ngokwamukela amasu aphambili, abakhiqizi bafinyelela amazinga angakaze abonwe okunemba, ukusebenza kahle, kanye nokusimama.

Njengoba amandla kanye nezindawo zezimboni ziqhubeka nokuvela, ukusungulwa komshini wesilinda esiphehla ugesi kuzodlala indima ebalulekile ekunikezeni amandla inqubekelaphambili, ukusuka kumandla avuselelekayo kuye ezinjinini zezindiza zesizukulwane esilandelayo. Amabhizinisi amukela lezi ntuthuko azohola indlela ekwakhekeni kwekusasa lapho ukunemba kuhlangabezana nokusebenza.

Isikhathi sokuthumela: Dec-16-2024