I-Magnetic vs Pneumatic Workholding ye-Aluminium Yeshidi Elincane

Umbhali: PFT, Shenzhen

Abstract

Ukwenziwa ngokunemba kwe-aluminium yeshidi elincane (<3mm) kubhekene nezinselelo ezinkulu zokubamba. Lolu cwaningo luqhathanisa amasistimu wokubopha kazibuthe nawomoya ngaphansi kwezimo zokugaya ze-CNC ezilawulwayo. Amapharamitha okuhlola afaka ukuhambisana kwamandla okubamba, ukuzinza kwe-thermal (20°C–80°C), ukuncibilika kokudlidliza, kanye nokuhlanekezela kwendawo. Ama-chuck e-pneumatic vacuum alondoloze ukucaba okungu-0.02mm kumashidi angu-0.8mm kodwa adinga izindawo zokuvala ezingaguquki. Ama-chuck kagesi anike amandla ukufinyelela kwe-axis engu-5 futhi anciphisa isikhathi sokusetha ngo-60%, nokho ama-eded currents abangelwa ukufudumeza kwendawo okudlula u-45°C ku-15,000 RPM. Imiphumela ikhombisa amasistimu e-vacuum alungiselela ukuqedwa kwendawo kumashidi >0.5mm, kuyilapho izixazululo zikazibuthe zithuthukisa ukuguquguquka kwe-prototyping esheshayo. Imikhawulo ihlanganisa izindlela ezixubile ezingahloliwe kanye nezinye ezisekelwe ekunamathiseleni.

1 Isingeniso

Amashidi e-aluminium azacile ezimbonini zamandla kusukela ku-aerospace (izikhumba ze-fuselage) kuya kugesi (ukwenziwa kukasinki wokushisa). Kodwa-ke izinhlolovo zezimboni zango-2025 zembula u-42% wamaphutha anembayo asuka ekunyakazeni kwezinto zokusebenza ngesikhathi somshini. Izinsimbi ezivamile zokubopha zivame ukuhlanekezela amashidi angaphansi kwe-1mm, kuyilapho izindlela ezisekelwe ku-tape zintula ukuqina. Lolu cwaningo lulinganisa izixazululo ezimbili ezithuthukisiwe: ama-chucks ka-electromagnetic leveraging control remanence systems kanye ne-pneumatic systems enokulawula kwe-multi-zone vacuum.

2 Indlela

2.1 Idizayini Yokuhlola

-

Izinto: 6061-T6 aluminium amashidi (0.5mm/0.8mm/1.2mm)

-

Izisetshenziswa:

-

Uzibuthe: I-GROB 4-axis electromagnetic chuck (0.8T ukuqina kwenkambu)

-

I-pneumatic: Ipuleti levacuum le-SCHUNK elinezindawo eziningi ezingama-36

-

-

Ukuhlola: Ukucaba komhlaba (i-laser interferometer), i-thermal imaging (FLIR T540), ukuhlaziywa kokudlidliza (3-axis accelerometers)

2.2 Izinqubo Zokuhlola

-

Ukuzinza Okuqinile: Linganisa ukuchezuka ngaphansi kwamandla aseceleni angu-5N

-

I-Thermal Cycling: Rekhoda izinga lokushisa ngesikhathi sokugaya (Ø6mm end mill, 12,000 RPM)

-

I-Dynamic Rigidity: Linganisa i-amplitude yokudlidliza kumafrikhwensi azwakalayo (500–3000 Hz)

3 Imiphumela kanye nokuhlaziya

3.1 Ukusebenza Kokubamba

| Ipharamitha | I-pneumatic (0.8mm) | Imagnetic (0.8mm) |

|---|---|---|

| Isilinganiso. Ukuhlanekezela | 0.02mm | 0.15mm |

| Isikhathi Sokusetha | 8.5 imiz | 3.2 imiz |

| I-Max Temp Rise | 22°C | 48°C |

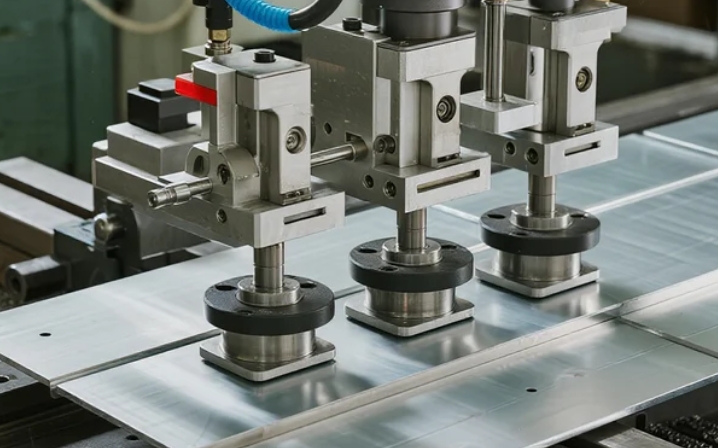

Umfanekiso 1: Amasistimu evacuum agcinwe <5μm ukuhluka kwendawo ngesikhathi sokugaya ubuso, kuyilapho ukubamba kukazibuthe kukhombisa ukuphakama komphetho okungu-0.12mm ngenxa yokwanda kwezinga lokushisa.

3.2 Izimpawu zokudlidliza

I-pneumatic chucks inciphise ama-harmonics ngo-15dB ku-2,200Hz - okubalulekile ekusebenzeni kokuqeda kahle. Ukusebenza kukazibuthe kubonise ukuphakama okungama-40% okuphezulu kumafrikhwensi okusebenzelana kwamathuluzi.

4 Ingxoxo

4.1 Ukuhwebelana Kwezobuchwepheshe

-

I-Pneumatic Advantage: Ukuzinza okuphezulu kwe-thermal kanye ne-vibration damping suit suits ezibekezelela kakhulu izinhlelo zokusebenza njengezisekelo ze-optical component.

-

I-Magnetic Edge: Ukulungiswa kabusha okusheshayo kusekela izindawo zesitolo semisebenzi eziphatha amasayizi amaqoqo ahlukahlukene.

Umkhawulo: Ukuhlolwa akufakiwe amashidi anembobo noma amafutha lapho ukusebenza kwe-vacuum kwehla >70%. Izixazululo ze-Hybrid zidinga ukutadisha kwesikhathi esizayo.

5 Isiphetho

Ngomshini omncane we-aluminium sheet machining:

-

Ukusebenza kwe-pneumatic kunikeza ukunemba okuphezulu kogqinsi>0.5mm ngezindawo eziqinile

-

Amasistimu kamagnetic anciphisa isikhathi esingasiki ngo-60% kodwa adinga amasu okupholisa okulawula ukushisa

-

Ukukhetha okungcono kakhulu kuncike ezidingweni zokuphuma kuqhathaniswa nezidingo zokubekezelelana

Ucwaningo lwesikhathi esizayo kufanele luhlole izimbambo eziguquguqukayo ze-hybrid kanye nemiklamo ye-electromagnetic interference.

Isikhathi sokuthumela: Jul-24-2025