I-Titanium's ukungasebenzi kahle kwe-thermal kanye nokusebenza kabusha kwamakhemikhali aphezulu kwenza kube lula ukonakala ngesikhathiCNC imishini. Ngenkathi i-geometry yamathuluzi kanye nemingcele yokusika ifundwe kahle, ukwenziwa ngcono kokupholisa kuhlala kusetshenziswa kancane ekusebenzeni komkhakha. Lolu cwaningo (olwenziwa ngo-2025) lubhekana naleli gebe ngokulinganisa ukuthi ukulethwa okupholisayo okuhlosiwe kuthuthukisa kanjani ikhwalithi yokuqedela ngaphandle kokufaka engozini ukuphuma.

Indlela yokwenza

1. Idizayini Yokuhlola

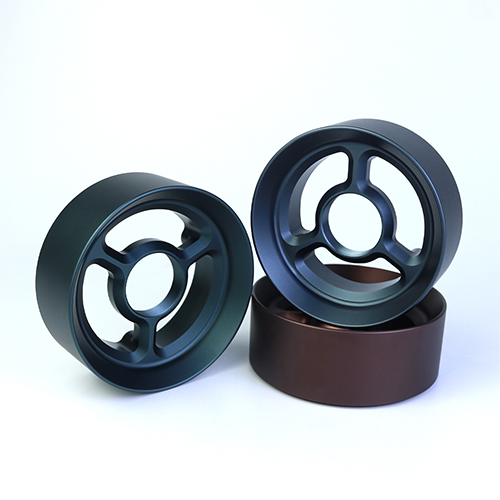

●Okubalulekile:Izinti ze-Ti-6Al-4V (Ø50mm)

●Izisetshenziswa:I-CNC ye-5-eksisi enokupholisa ngethuluzi (ibanga lokucindezela: 20–100 bar)

●Amamethrikhi alandelelwe:

Ubulukhuni bobuso (Ra) ngephrofayili yokuxhumana

Ukugqokwa kwe-flank yethuluzi kusetshenziswa isithombe se-microscope ye-USB

Izinga lokushisa lendawo yokusika (ikhamera ye-FLIR eshisayo)

2. Izilawuli zokuphindaphinda

●Ukuhlolwa okuphindwe kathathu ngesethi yepharamitha ngayinye

● Ukufakwa kwamathuluzi kushintshiwe ngemva kokuhlolwa ngakunye

● Izinga lokushisa le-ambient lizinzile ku-22°C ±1°C

Imiphumela & Ukuhlaziya

1. I-Coolant Pressure vs. Surface Finish

●Ingcindezi (ibha):20 50 80

●Isilinganiso. I-Ra (μm) :3.2 2.1 1.4

●I-Tool Wear (mm):0.28 0.19 0.12

Ukupholisa umfutho ophezulu (amabha angu-80) kwehlise i-Ra ngo-56% uma kuqhathaniswa nesisekelo (amabha angu-20).

2. Imithelela Yokumisa Imbobo

Ama-nozzle anama-engeli (15° ukuya kwithiphu yethuluzi) asebenza ngokungaphezu kokusethwa kweradial ngokuthi:

● Ukunciphisa ukunqwabelana kokushisa ngo-27% (idatha eshisayo)

●Ukunweba impilo yamathuluzi ngo-30% (izilinganiso zokugqoka)

Ingxoxo

1. Izindlela Ezibalulekile

●Ukukhishwa Kwe-chip:Isipholile esinengcindezi ephezulu siphula ama-chips amade, sivimbele ukusika kabusha.

●Ukulawula Okushisayo:Ukupholisa okwenziwe kwasendaweni kunciphisa ukuhlanekezela kwengcezu yokusebenza.

2. Ukulinganiselwa Okungokoqobo

● Idinga ukusethwa okulungisiwe kwe-CNC (ubuncane bomthamo wepompo yamabha angama-50)

● Ayibizi kakhulu ekukhiqizeni ivolumu ephansi

Isiphetho

Ukuthuthukisa ingcindezi epholile kanye nokuqondanisa kwenozzle kuthuthukisa kakhulu ukuqedwa kwe-titanium surface. Abakhiqizi kufanele babeke phambili:

●Ukuthuthukela kumasistimu wokupholisa amabha angu-≥80

● Ukwenza izivivinyo zokubeka umlomo wombhobho wamathuluzi athile

Ucwaningo olwengeziwe kufanele luhlole ukupholisa okuxubile (isb, i-cryogenic+MQL) kuma-alloys okunzima ukuya komshini.

Isikhathi sokuthumela: Aug-01-2025