Namuhla's esheshayoukukhiqiza emhlabeni wonke, amabhizinisi kuzo zonke izimboni ezihlukahlukene athembela kakhulu ekwenzeni imishini ukuze ahlangabezane nesidingo esikhulayo sezingxenye zobunjiniyela obunembayo. Njengoba izimboni zithuthuka futhi nemiklamo yemikhiqizo iba inkimbinkimbi, ikhono lokukhiqiza izingxenye zangokwezifiso ezinemininingwane eqondile alikaze libe baluleke kakhulu. Ukwenza ngokwezifiso kunikeza isixazululo esiguquguqukayo, esingabizi, nesisebenza ngempumelelo ezinkampanini ezifuna izinto zekhwalithi ephezulu, ezenziwe ngendlela efanelekile ezihambisana nezidingo zazo ezihlukile.

Ukusuka emkhathini kuya emishinini yezokwelapha, eyezimoto kuye kwezikagesi, isidingo sezingxenye ezenziwe ngomshini siyanda. Lesi sihloko sihlola ukuthi kuyini ukwenziwa kwemishini yangokwezifiso, kungani kuzuza ezimbonini zonkana, izinzuzo ezikunikezayo, nokuthi kuyiguqula kanjani indawo yokukhiqiza.

Iyini i-Custom Machining?

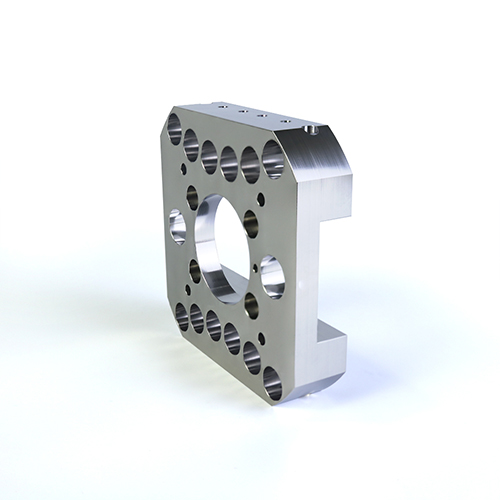

Ukwenza ngokwezifiso isho inqubo yokukhiqiza lapho ucezu lokusebenza (ngokuvamile olwenziwa ngensimbi, ipulasitiki, noma izinto eziyinhlanganisela) lubunjwa, lusikwe, noma luqedwe ukuhlangabezana nobukhulu obuthile nokubekezelelwa. Ngokungafani nezingxenye zendabuko, ezikhiqizwe ngobuningi, ukwenziwa kwemishini ngokwezifiso kuhambisana nezidingo eziqondile zekhasimende, okuvumela ijometri eyinkimbinkimbi, ukubekezelelana okuqinile, kanye nokuqedwa kwekhwalithi ephezulu.

Ukusebenzisa ubuchwepheshe obufanaCNC(Computer Numerical Control) ukwenza imishini, ukugaya, ukujika, ukugaya, kanye nokubhola, inkanikhiqiza izingxenyeyezinkimbinkimbi ezihlukene—kusuka kwezilula, izingcezu ezisebenzayo kuye kweziyinkimbinkimbi, izingxenye ezinembe kakhulu zezimboni ezifana ne-aerospace, ezezimoto, ezokwelashwa, nokunye.

Kungani Imishini Engokwezifiso Izuza Ukuduma

Kunezici ezimbalwa eziqhube ukuthembela okukhulayo emishinini yangokwezifiso kuzo zonke izimboni. Lokhu kubandakanya:

●Ukwandisa Ubunkimbinkimbi Kumklamo:Njengoba izimboni zicindezela imingcele yokuqanjwa kabusha, imiklamo yemikhiqizo iba nzima kakhulu. Ukwenza ngokwezifiso imishini kuvumela abakhiqizi ukuthi bakhe izingxenye ezihlangabezana nokucaciswa okuyinkimbinkimbi, ezinikeza ukuguquguquka kokukhiqiza izingxenye ezinomumo oyinkimbinkimbi, amajika, nezici ezinemininingwane okungaba nzima noma okungenzeki ukuzifeza ngezindlela ezivamile zokukhiqiza ngobuningi.

● I-Material Versanity:Ukwenza ngokwezifiso kulungele izinhlobonhlobo zezinto ezibonakalayo, kusukela ezinsimbi (njenge-aluminium, insimbi engagqwali, ne-titanium) kuya kumapulasitiki (njenge-polycarbonate nenayiloni) nezinhlanganisela. Lokhu kuguquguquka kuvumela abakhiqizi ukuthi bakhethe into engcono kakhulu yohlelo lwabo lokusebenza oluthile, noma ngabe badinga izinto ezingasindi, eziqinile, noma ezimelana nokugqwala.

● Ukunemba Okuphezulu Nokubekezelela:Enye yezinzuzo eziyinhloko zomshini wangokwezifiso yikhono lokufinyelela ukubekezelela okuqinile (ngokunemba ±0.001 amayintshi noma ngaphansi). Ezimbonini ezifana nemishini yezokwelapha, i-aerospace, ne-electronics, ukunemba kubalulekile. Ukwenza ngokwezifiso kuqinisekisa ukuthi zonke izingxenye zilingana kahle futhi zisebenza ngokwethembeka, ngisho nasezinhlelweni ezibaluleke kakhulu zenjongo.

● Ukukhiqizwa Kwevolumu Ephansi Okungabizi kakhulu:Yize izindlela zokukhiqiza zevolumu ephezulu njengokubunjwa komjovo noma ukufakwa kwe-die-casting kuvame ukudinga amathuluzi abizayo kanye nokubunjwa, ukwenziwa kwemishini yangokwezifiso kungabiza izindleko eziphansi zokukhiqiza ezimaphakathi. Njengoba ingadingi ukudalwa kwamathuluzi akhethekile, izindleko ezihambisana nokwenza ngokwezifiso zivame ukuba ngaphansi, ikakhulukazi ukwenza i-prototyping noma ukukhiqizwa kwenqwaba encane.

● I-Prototyping esheshayo nokuphindaphinda:Ukwenza ngokwezifiso kuyisixazululo esifanelekile se-prototyping esheshayo. Onjiniyela bangakhiqiza ngokushesha i-prototype, bayihlole, futhi baphindaphinde ekwakhiweni ngaphandle kokubambezeleka okukhulu noma izindleko. Lobu buchule busheshisa inqubo yokuthuthukiswa futhi kunciphisa isikhathi sokumaketha kwemikhiqizo emisha.

Isebenza Kanjani Imishini Yangokwezifiso?

Inqubo yokwenza imishini yangokwezifiso ibandakanya izinyathelo ezimbalwa ezibalulekile, ngayinye ehloselwe ukuqinisekisa ukuthi ingxenye yokugcina ihlangabezana nemininingwane eshiwo yikhasimende:

● Isigaba sokuklama:Isinyathelo sokuqala ekwenzeni ngokwezifiso ukudalwa komklamo onembile. Lokhu ngokuvamile kwenziwa kusetshenziswa isofthiwe ye-CAD (Computer-Aided Design), evumela onjiniyela nabaklami ukuthi bakhe amamodeli we-2D noma we-3D wengxenye. Umklamo we-CAD ube usuguqulwa ube ikhodi efundeka ngomshini, ngokuvamile osesimweni sekhodi ye-G.

● Ukukhetha Okubalulekile:Ngokusekelwe emsebenzini wengxenye kanye nezidingo ezithile zephrojekthi, ukwaziswa okufanele kuyakhethwa. Izinto ezijwayelekile zifaka izinsimbi ezifana nensimbi engagqwali, i-aluminium, i-titanium, nethusi, kanye namapulasitiki obunjiniyela afana ne-Delrin, inayiloni, ne-PTFE. Izinto ezinezici ezithile ezinjengokumelana nokushisa, ukuguquguquka, noma ukumelana nokugqwala zikhethwa ngokusekelwe ekusetshenzisweni okuhlosiwe.

● Inqubo Yomshini:Kusetshenziswa umshini we-CNC, i-material isikwa kahle, yakhiwe, futhi yaqedwa. Umshini we-CNC ulandela imiyalelo yekhodi ye-G ukuze wenze imisebenzi ehlukahlukene, okuhlanganisa ukugaya, ukujika, ukubhola, noma ukugaya. Umshini ungase ube nezimbazo eziningi zokunyakaza (ngokuvamile 3, 4, noma 5 izimbazo) ukuvumela ukusika nokubunjwa okuyinkimbinkimbi, okunezinhlangothi eziningi.

● Ngemuva kokucubungula:Ngemva kwenqubo yomshini, izinyathelo zokuqeda ezengeziwe zingase zidingeke, njengokukhipha (ukususwa kwemiphetho ebukhali), ukupholisha, noma ukumboza. Lezi zinyathelo zangemva kokucubungula zisiza ukufeza indawo oyithandayo futhi zithuthukise ukubukeka nokusebenza kwengxenye.

● Ukulawula Ikhwalithi:Ukulawulwa kwekhwalithi kuyisici esibalulekile somshini wangokwezifiso. Izingxenye ziyahlolwa ukuze kuqinisekiswe ukuthi ziyahlangabezana nemibandela edingekayo kanye nokubekezelela. Lokhu kungabandakanya ukuhlola okubonakalayo, ukukalwa kobukhulu kusetshenziswa amathuluzi afana ne-CMM (Imishini Yokulinganisa Yokuhlanganisa), nokuhlola amandla, ukuqina, nezinye izici zokusebenza.

● Ukulethwa:Uma ingxenye isidlulile ukulawulwa kwekhwalithi, isilungele ukulethwa ekhasimendeni. Ukushintsha okusheshayo nokuvumelana nezimo komshini wangokwezifiso kuqinisekisa ukuthi abakhiqizi bangakwazi ukuhlangabezana nezikhathi eziqinile zokukhiqiza.

Izinzuzo Eziyinhloko Zomshini Wangokwezifiso

Ukwenza ngokwezifiso kunikeza izinzuzo eziningi, okukwenza kube yinketho ekhethwayo kumabhizinisi afuna ukukhiqiza izingxenye zekhwalithi ephezulu, ezibunjwe ngokunemba.

● Ukuvumelana nezimo Kudizayini Nokukhiqiza:Ukwenza ngokwezifiso kungaphatha imiklamo ehlukahlukene kanye nezinto zokwakha, okwenza kube inqubo yokukhiqiza evumelana nezimo kakhulu. Kungakhathaliseki ukuthi udinga ingxenye elula noma ingxenye eyinkimbinkimbi kakhulu, enezici eziningi, ukukhanda ngokwezifiso kungabhekana nezidingo zakho.

● Ukunemba Nokunemba:Imishini ye-CNC ihlinzeka ngokunemba okungenakuqhathaniswa, okuyenza ifaneleke ezinhlelweni lapho yonke ingxenye yemilimitha ibala khona. Izingxenye ezikhiqizwe ngomshini wangokwezifiso zingafinyelela ukubekezelelana okuqine njengamayintshi angu-±0.001, iqinisekise ukuthi umkhiqizo wokugcina ulingana kahle futhi usebenza njengoba kuhlosiwe.

● Ibiza Kakhulu Ekugijimeni Kwevolumu Ephansi:Ezimbonini ezidinga amaqoqo amancane noma izingxenye zangokwezifiso, ukwenza ngokwezifiso kungaba yisixazululo esingabizi kakhulu kunezindlela zokukhiqiza ezijwayelekile. Ukuntuleka kwezindleko zamathuluzi angaphambili kanye nekhono lokulungisa ngokushesha imiklamo yezinguquko noma izibuyekezo kuyenza ibe yisixazululo esifanelekile sokugijima kokukhiqiza okuphansi kuya kokuphakathi.

● I-High-Quality Surface Finishes:Ukwenza ngokwezifiso kungafinyelela ukuqedwa okuphezulu okuphezulu, okubalulekile kukho kokubili ukubukeka nokusebenza kwezingxenye. Izinyathelo zokucubungula ngemva kokupholishwa, ukunameka, nokugcotshwa kwe-anodizing zingasetshenziswa ukuthuthukisa izici ezingaphezulu zezingxenye, ukuqinisekisa ukuthi zihlangabezana kokubili nezidingo zobuhle nokusebenza.

● Ukushintsha Okusheshayo:Ikhono lokukhiqiza ngokushesha ama-prototypes noma izingxenye ezilungele ukukhiqiza lenza ukukhanda ngokwezifiso kube inketho yokuya kumabhizinisi adinga ukunciphisa isikhathi sokuya emakethe. Uma umklamo usuphothuliwe, imishini ye-CNC ingaqala ukukhiqiza izingxenye cishe ngokushesha, ifinyeze kakhulu umjikelezo wokuthuthukiswa.

Izimboni Ezihlomula Ngomshini Ongokwezifiso

● Umkhathi:Ukwenza ngokwezifiso kubalulekile ekwenziweni kwe-aerospace, lapho izingxenye kufanele zihlangabezane nezindinganiso eziqinile zokuphepha nokusebenza. Izingxenye zenjini, abakaki, izingxenye zegiya lokuhlala, nama- turbine blades kuvamise ukwenziwa ngokwezifiso ukuze kuhlangatshezwane nezidingo zomkhakha we-aerospace.

● Amadivayisi Ezokwelapha:Emkhakheni wezokwelapha, umshini wangokwezifiso usetshenziselwa ukwakha izingxenye ezifana namathuluzi okuhlinza, izimila, nezitho zokufakelwa. Lezi zingxenye zidinga ukunemba okuphezulu futhi ngokuvamile kufanele zihambisane nemvelo noma zimelane nokugqwala nokuguga.

● Ezezimoto:Ukwenza ngokwezifiso imishini kusetshenziselwa ukwakha izingxenye zezimoto ezibalulekile njengezingxenye zenjini, amabhuleki, izinto ezimisiwe, nezingxenye zangaphakathi. Imishini ivumela ukunemba okuphezulu nokuqina, okubalulekile ekuphepheni nasekusebenzeni kwemoto.

● Ezogesi:Imboni ye-elekthronikhi incike emishinini yangokwezifiso yezingxenye ezifana nezivalekile, izixhumi, namasinki okushisa. Lezi zingxenye zibalulekile ekuvikeleni izinto zikagesi ezibucayi kanye nokuqinisekisa ukusebenza okuthembekile.

● Izisetshenziswa zezimboni:Imishini eyenziwe ngokwezifiso isetshenziswa ekukhiqizeni izingxenye eziyinkimbinkimbi zemishini nemishini yezimboni. Kungakhathaliseki ukuthi ikhiqiza amagiya, ama-shaft, noma izakhi ze-hydraulic, ukwenza ngokwezifiso kunikeza ukunemba nokuqina okudingekayo ezisetshenziswa zezimboni.

Ikusasa Lokwenza Ngokwezifiso

Ikusasa lemishini yangokwezifiso liqhakazile, nentuthuko kwezobuchwepheshe iqhubeka nokuqhubekisela phambili imboni. I-automation, ukuhlanganiswa kwe-AI, nezinto ezithuthukisiwe kulindeleke ukuthi zibambe iqhaza elikhulu ekuthuthukiseni ukunemba, ukusebenza kahle kanye nokusimama.

● I-AI Nokuzenzakalela:Ukuhlanganiswa kwe-AI nokufunda komshini ezinqubweni zemishini ye-CNC kulindeleke ukuthi kuthuthukise amandla emishini ukuze ivumelane nezimo nokusebenza kahle ngesikhathi sangempela, kuthuthukiswe ukusebenza kahle kanye nokunciphisa isikhathi sokuphumula.

● Ukuhlanganiswa Kokukhiqiza Okungeziwe:Inhlanganisela yokuphrinta kwe-3D (ukukhiqiza okungeziwe) nokwenza ngokwezifiso isivele iguqula izimboni ngokunikeza ukuguquguquka okukhulu komklamo. Izinqubo zokukhiqiza ezixubile ezihlanganisa kokubili ukuphrinta kwemishini nokuphrinta kwe-3D ziya ngokuya zibanda.

● Ukuzinza:Njengoba ukusimama kuba into esemqoka okugxilwe kuyo ezimbonini zonkana, ukwenziwa kwemishini yangokwezifiso kuzoqhubeka nokuvela ngokugcizelela ekwehliseni udoti wezinto ezibonakalayo nokusebenzisa izinto ezigaywa kabusha noma ezilungele imvelo.

Isikhathi sokuthumela: Jun-09-2025