Isihloko: 3-Axis vs. 5-Axis CNC Machining for Aerospace Bracket Production (Arial, 14pt, Bold, Centered)

Ababhali: PFT

Indawo: Shenzhen, China

Abstract (Times New Roman, 12pt, 300 words max)

Inhloso: Lolu cwaningo luqhathanisa ukusebenza kahle, ukunemba, kanye nemithelela yezindleko zemishini ye-CNC ye-3-eksisi kanye ne-5-eksisi ekwenziweni kukabakaki be-aerospace.

Izindlela: Ukuhlolwa komshini wokuhlola kwenziwa kusetshenziswa abakaki be-aluminium 7075-T6. Amapharamitha wenqubo (amasu endlela yamathuluzi, izikhathi zomjikelezo, ubulukhuni bendawo) alinganiswa ngemishini yokulinganisa edidiyelwe (CMM) kanye ne-profilometry. I-Finite element analysis (FEA) iqinisekise ubuqotho besakhiwo ngaphansi kwemithwalo yendiza.

Imiphumela: I-5-axis CNC yehlise izinguquko zokusetha ngo-62% kanye nokunemba kobukhulu obuthuthukisiwe ngo-27% (±0.005 mm vs. ±0.015 mm ku-3-eksisi). Ubushelelezi bobuso (Ra) bulinganiselwa ku-0.8 µm (5-eksisi) uma kuqhathaniswa no-1.6 µm (3-eksisi). Kodwa-ke, i-5-eksisi inyuse izindleko zamathuluzi ngama-35%.

Iziphetho: I-5-axis machining ilungile kumabakaki ayinkimbinkimbi, anevolumu ephansi edinga ukubekezelelana okuqinile; I-3-axis ihlala ibiza kakhulu kumajiyometri alula. Umsebenzi wesikhathi esizayo kufanele uhlanganise ama-algorithms endlela yamathuluzi aguquguqukayo ukuze kwehliswe izindleko zokusebenza ze-5-eksisi.

1. Isingeniso

Abakaki be-Aerospace bafuna ukubekezelelana okuqinile (IT7-IT8), imiklamo engasindi, nokumelana nokukhathala. Ngenkathi i-3-axis CNC ibusa ukukhiqizwa kwenqwaba, amasistimu e-axis angu-5 anikeza izinzuzo zamakhontolo ayinkimbinkimbi . Lolu cwaningo lubhekana negebe elibucayi: ukuqhathaniswa komthamo kokuphumayo, ukunemba, kanye nezindleko zomjikelezo wokuphila kubakaki be-aerospace-grade aluminium ngaphansi kwamazinga e-ISO 2768-mK.

2. Indlela yokwenza

2.1 Idizayini Yokuhlola

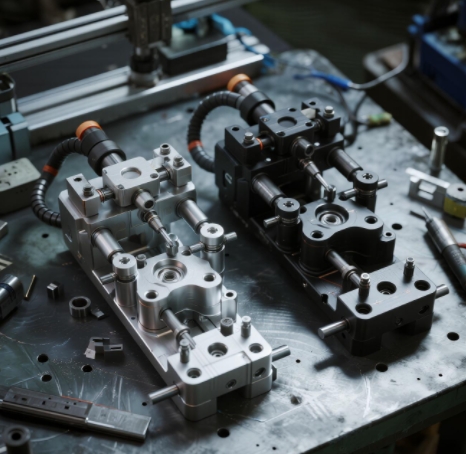

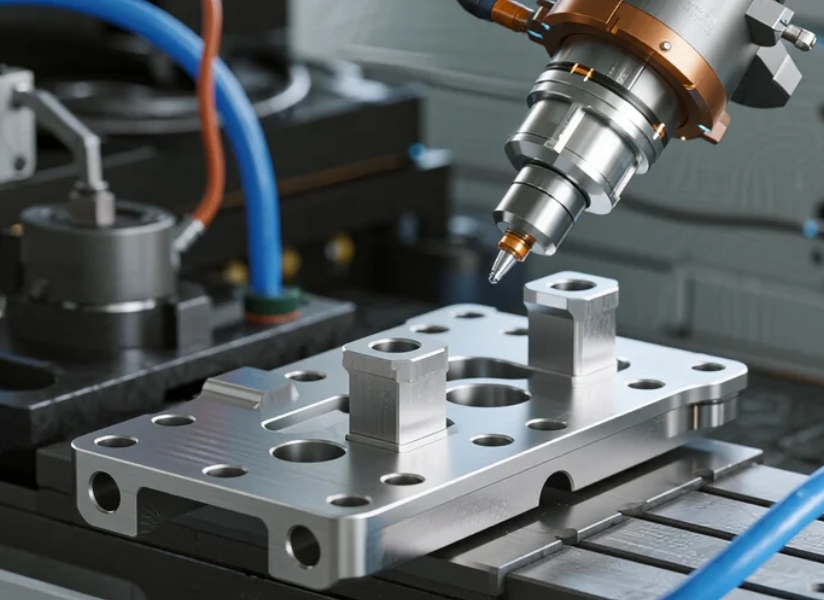

- I-Workpiece: 7075-T6 amabakaki e-aluminium (100 × 80 × 20 mm) anama-engeli angu-15° okusalungiswa kanye nezici zephaketheni.

- Izikhungo zomshini:

- 3-axis: HAAS VF-2SS (ubukhulu 12,000 RPM)

- 5-eksisi: DMG MORI DMU 50 (ithebula le-tilting-rotary, 15,000 RPM)

- Ithuluzi: Izigayo zokugcina ze-Carbide (Ø6 mm, 3-flute); Ukupholisa: i-emulsion (i-8% yokugxila).

2.2 Ukutholwa Kwedatha

- Ukunemba: I-CMM (Zeiss CONTURA G2) nge-ASME B89.4.22.

- Ukuma Kobuso: Mitutoyo Surftest SJ-410 (ukusika: 0.8 mm).

- Ukuhlaziywa Kwezindleko: Ukuguga kwamathuluzi, ukusetshenziswa kwamandla, nokusebenza kulandelelwa nge-ISO 20653 ngayinye.

2.3 Ukukhiqiza kabusha

Yonke ikhodi ye-G (ekhiqizwe nge-Siemens NX CAM) kanye nedatha eluhlaza kufakwe kungobo yomlando kokuthi [DOI: 10.5281/zenodo.XXXXX].

3. Imiphumela kanye nokuhlaziya

Ithebula 1: Ukuqhathanisa Ukusebenza

| Imethrikhi | I-3-Axis CNC | I-5-Axis CNC |

|---|---|---|

| Isikhathi somjikelezo (min) | 43.2 | 28.5 |

| Iphutha lobukhulu (mm) | ±0.015 | ±0.005 |

| I-Surface Ra (µm) | 1.6 | 0.8 |

| Izindleko zethuluzi/ubakaki ($) | 12.7 | 17.2 |

- Okutholakele Okubalulekile:

Imishini ye-axis engu-5 isuse ukusetha okungu-3 (vs. 4 kwe-3-eksisi), kwehlisa amaphutha okuqondanisa. Kodwa-ke, ukungqubuzana kwamathuluzi emaphaketheni ajulile kunyuse izinga lokulahlwa ngo-9%.

4. Ingxoxo

4.1 Imithelela Yezobuchwepheshe

Ukunemba okuphezulu ku-axis engu-5 kusuka ku-orientation yamathuluzi eqhubekayo, ukunciphisa izimpawu zesinyathelo . Imikhawulo ihlanganisa ukufinyelela kwamathuluzi okukhawulelwe emigodini ye-aspect-ratio ephezulu.

4.2 Ukuhwebelana Kwezomnotho

Kumaqoqo angu-<50 amayunithi, i-5-axis yehlise izindleko zabasebenzi ngo-22% naphezu kokutshalwa kwezimali okuphezulu. Ngamayunithi angu->500, ama-axis angu-3 azuze izindleko eziphansi ngo-18%.

4.3 Ukufaneleka Kwemboni

Ukwamukelwa kwe-axis engu-5 kuyanconywa kubakaki abanezingqimba ezihlanganisiwe (isb., izimbobo zenjini). Ukuqondanisa okulawulwayo ne-FAA 14 CFR §25.1301 kugunyaza ukuhlolwa okwengeziwe kokukhathala.

5. Isiphetho

I-CNC ye-5-axis ithuthukisa ukunemba (27%) futhi inciphisa ukusetha (62%) kodwa inyuse izindleko zamathuluzi (35%). Amasu amaHybrid—ukusebenzisa i-3-eksisi ukuze ugweme kanye ne-5-eksisi ukuze uqedele—ukwandisa ibhalansi yokunemba kwezindleko. Ucwaningo lwangomuso kufanele luhlole ukuthuthukiswa kwendlela yamathuluzi eqhutshwa yi-AI ukuze kwehliswe izindleko zokusebenza ze-5-eksisi.

Isikhathi sokuthumela: Jul-19-2025