I-High-Speed Machineing yezingxenye ze-Aluminium

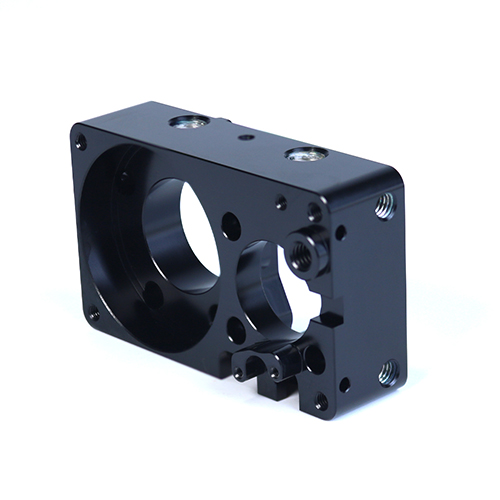

Uhlolojikelele Lomkhiqizo

Uma usebenza neizingxenye ze-aluminium-kungakhathaliseki ukuthi i-aerospace, i-automotive, noma i-electronics yabathengi-high-speed machining (HSM)kungaba isiguquli somdlalo. Akukhona nje ukusika ngokushesha; kumayelanaama-surface finishes angcono, ukubekezelelana okuqinile, nezindleko eziphansi.

I-Aluminium ingenye yezintoizinsimbi ezilula emshinini, kodwa ukukwenza ngesivinini esikhulu kuvula izinzuzo ezengeziwe:

✔ 3-5x Ukusika Ngokushesha - Izikhathi zomjikelezo ezincishisiwe zisho izingxenye eziningi ngehora.

✔ I-Superior Surface Finish - Kudingeka ukucubungula okuncane kwangemuva.

✔ Ukuphila Kwethuluzi Elinwetshiwe - Amasu afanelekile we-HSM anciphisa ukuguga kwamathuluzi.

✔ Amajiyometri Ayinkimbinkimbi - Alungele izindonga ezincane nemininingwane emihle.

Izimboni Ezihlomula Kakhulu:

● I-Aerospace (Izingxenye ze-Airframe, izingxenye ze-drone)

●Izimoto (Amabhulokhi enjini, izindlu zokudlulisela)

● Ezogesi (Amasinki okushisa, izindawo ezivalekile)

●Ezokwelapha (Amathuluzi okuhlinza angasindi, izindlu zedivayisi)

I-Aluminium isika ngokuhlanzekile kuma-RPM aphezulu ngaphandle kokwanda kokushisa okudlulele.

2. Kwenzelwe Okuphakelayo Amazinga

Ibhalansi isivinini nokunemba ukuvimbela ukuchezuka kwamathuluzi.

3. Izinyathelo Ezincane Ezincane, Ukunyakaza Okusheshayo

Esikhundleni sokusikeka okujulile, i-HSM isebenzisa amaphasi alula, asheshayo ukuze enze kahle.

4. Izindlela Zamathuluzi Ezithuthukisiwe (Ukugaya iTrochoidal, Ukucwecwa)

Yehlisa ukucindezelwa kwamathuluzi futhi ithuthukise ukuphuma kwe-chip.

Hhayi bonke i-aluminiumliyalingana. Nazi ukukhetha okuphezulu komshini wejubane eliphezulu:

●6061-T6:Iqinile, iyashisela, iyashintshashintsha

●7075-T6:Ibanga le-Aerospace, elinamandla kakhulu

●2024-T3:Ukumelana nokukhathala okuphezulu

●5052:Ukumelana nokugqwala okuhle kakhulu

●Izindleko Zokukhiqiza Eziphansi - Ukwenza ngokushesha = isikhathi esincane somsebenzi.

●Ukunemba Okungcono - Igcina ukubekezelelana okuqinile (± 0.025mm noma okungcono).

●Ukushisa Okuncishisiwe & Warping - Ivimbela ukuhlanekezelwa kwezinto.

●I-Smoother Finish - Ngokuvamile kuqeda isidingo sokupholisha.

Ukwenza imishini enesivinini esikhulu kuyisa izingxenye ze-aluminium ezingeni elilandelayo—ukukhiqiza okusheshayo, ukuqedwa okungcono, nezindleko eziphansi. Noma ngabe wenza amafreyimu e-drone, izingxenye zemoto, noma izisetshenziswa zezokwelapha, i-HSM ingakunikeza umkhawulo wokuncintisana.

Siyaziqhenya ngokubamba izitifiketi ezimbalwa zokukhiqiza zezinsizakalo zethu zemishini ze-CNC, ezibonisa ukuzibophezela kwethu kwikhwalithi nokwaneliseka kwamakhasimende.

1,I-ISO 13485: ISItifiketi SoHLELO LOKUPHATHWA KWAMADIVISI EMIDILI

2,I-ISO9001:UHLELO LOKUPHATHWA KWEQUALITY

3,IATF16949,AS9100,SGS,CE,I-CQC,I-RoHS

● I-CNCmachining enhle kakhulu ye-laser eqoshiwe ehamba phambili ye-Ive everseensofar Ikhwalithi enhle iyonke, futhi zonke izingcezu zazipakishwe ngokucophelela.

● Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo Le nkampani yenza umsebenzi omuhle ngempela ngekhwalithi.

● Uma kunenkinga bayashesha ukuyilungisaUkuxhumana okuhle kakhulu nezikhathi zokuphendula ngokushesha Le nkampani ihlale yenza engikucelayo.

● Baze bathole noma imaphi amaphutha okungenzeka ukuthi sesiwenzile.

● Sesisebenzelana nale nkampani iminyaka eminingana futhi besilokhu sihoxisa isevisi eyisibonelo.

● Ngijabule kakhulu ngekhwalithi evelele noma izingxenye zami ezintsha.I-pnce inokuncintisana kakhulu futhi isevisi yekhasimende iphakathi kwezingcono kakhulu engake ngaba nazo.

● Ikhwalithi esheshayo ye-tumaround, kanye nesevisi yamakhasimende ehamba phambili noma yikuphi emhlabeni.

Q:Ngingayithola ngokushesha kangakanani i-prototype ye-CNC?

A:Izikhathi zokuhola ziyahlukahluka kuye ngengxenye yobunkimbinkimbi, ukutholakala kwezinto ezibonakalayo, nezimfuneko zokuqeda, kodwa ngokuvamile:

●Ama-prototypes alula:1-3 izinsuku zebhizinisi

●Amaphrojekthi ayinkimbinkimbi noma anezingxenye eziningi:5-10 izinsuku zebhizinisi

Isevisi esheshayo ivame ukutholakala.

Q: Yimaphi amafayela okuklama okudingeka ngiwanikeze?

A:Ukuze uqalise, kufanele uthumele:

● Amafayela e-3D CAD (okungcono abe ku-STEP, IGES, noma ifomethi ye-STL)

● Imidwebo ye-2D (i-PDF noma i-DWG) uma ukubekezelela okuthile, izintambo, noma ukuqedwa kwendawo kuyadingeka

Q: Ungakwazi yini ukuphatha ukubekezelelana okuqinile?

A:Yebo. Imishini ye-CNC ilungele ukufeza ukubekezelelana okuqinile, ngokuvamile ngaphakathi:

● ±0.005" (±0.127 mm) okujwayelekile

● Ukubekezelela okuqinile kuyatholakala uma ucelwa (isb, ±0.001" noma okungcono)

Q: Ingabe i-CNC prototyping ilungele ukuhlolwa okusebenzayo?

A:Yebo. Ama-prototypes e-CNC enziwe ngezinto zangempela zebanga lobunjiniyela, okuwenza alungele ukuhlolwa okusebenzayo, ukuhlolwa kokulingana, nokuhlolwa kwemishini.

Q: Ingabe unikeza ukukhiqizwa kwevolumu ephansi ngaphezu kwama-prototypes?

A:Yebo. Izinsizakalo eziningi ze-CNC zihlinzeka ngokukhiqizwa kwebhuloho noma ukukhiqizwa kwevolumu ephansi, ilungele amanani ukusuka ku-1 kuya kumayunithi angamakhulu amaningana.

Umbuzo:Ingabe umklamo wami uyimfihlo?

A:Yebo. Amasevisi ahloniphekile e-CNC ahlala esayina Izivumelwano Zokungadaluli (ama-NDA) futhi aphathe amafayela akho kanye nempahla esunguliwe ngobuhlakani obugcwele.