Abahlinzeki beMachining bezingxenye zokunemba okuphezulu

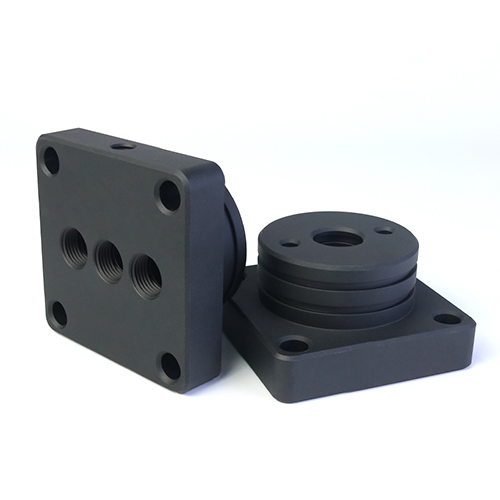

Uhlolojikelele Lomkhiqizo

Eqinisweni, uma usesha"abahlinzeki bemishini bemishini yokunemba okuphezulu,"awugcini nje ngokuthenga izingxenye; utshala emkhiqizweni wokugcina.

Ngisho nephutha elincane kakhulu, ukuchezuka kwengxenye nje yemilimitha, kungonakalisa yonke iphrojekthi. Sikhuluma ngezingxenye ezisetshenziswa kumishini yezokwelapha, amasistimu we-aerospace, nama-prototypes abalulekile e-R&D. Ingozi iphezulu kakhulu, futhi umkhawulo wephutha unguziro.

High ukunemba izingxenye machiningibhekisela ohlelweni lokusebenzisa izinto ezithuthukisiwe nobuchwepheshe ukuze kukhiqizwe izingxenye ezinokubekezelela okuqinile—ngokuvamile phakathi kwezingxenyana zemilimitha noma ububanzi be-micron. Lezi zingxenye ngokuvamile zenziwe ngokusetshenziswaCNC (Computer Numerical Control) imishini, ekwazi ukwenza umnyakazo onembe kakhulu ngokusekelwe kumiklamo ekhiqizwe ngekhompuyutha.

Eminye imisebenzi ebalulekile ehilelekile ekwenzeni imishini enembayo ihlanganisa:

●I-CNC Milling and Turning:Isetshenziselwa ukubumba izingxenye ezinamajiyometri ayinkimbinkimbi noma amafomu angama-cylindrical.

●I-EDM (Umshini Wokukhipha Ugesi):Inqubo yokudala izimo eziyinkimbinkimbi kakhulu noma izinto eziqinile okunzima ukuzisebenzisa ngezindlela zendabuko.

●Ukugaya nokupholisha:Ukuze uthole ukuqedwa okubushelelezi kanye nobukhulu obuqondile.

Lezi zindlela zisetshenziselwa ukwenza izingxenye ezihlangabezana nezindinganiso eziqine kakhulu, okuhlanganisa nalezo ezisemkhathini, ezimbonini zezimoto, zezokwelapha, neze-electronics.

Uma uthola izingxenye ezinembayo eziphezulu, ukukhetha kwakho umphakeli kungaba nomthelela omkhulu ekusebenzeni kwakho kokukhiqiza, ikhwalithi yomkhiqizo, ngisho nesisekelo sakho. Ukusebenza nomhlinzeki womshini ofanele kuqinisekisa:

●Imikhiqizo Yekhwalithi Ephezulu:Abahlinzeki bemishini enembile abanolwazi olufanele kanye namathuluzi bangaletha izingxenye ezihlangabezana nezimfuneko zakho eziqondile.

●Ukulethwa Ngesikhathi:Ukubambezeleka kwe-supply chain kungadala umonakalo ohlelweni lwakho lokukhiqiza. Umhlinzeki onokwethenjelwa ongaletha izingxenye ngesikhathi ubaluleke kakhulu.

●Izixazululo Ezingabizi:Yize ukwenza imishini enembayo ephezulu kungabiza, umphakeli omuhle angakusiza uthole izixazululo ezongayo ngaphandle kokubeka engcupheni ikhwalithi.

●Ukuguquguquka Komklamo:Abahlinzeki abangcono kakhulu banikeza ukwesekwa kwedizayini futhi bayakwazi ukwenza izinguquko ukuze bahlangabezane nezidingo zokukhiqiza eziguqukayo.

Umhlinzeki ofanele akagcini nje ngokwenza izingxenye—basiza ukuthuthukisa inqubo yokukhiqiza futhi baqinisekise ukuthi uhlangabezana nezidingo zamakhasimende akho ngaphandle kwezihibe.

Lapho ukhetha umphakeli womshini wezingxenye ezinemba okuphezulu, kunezici ezimbalwa ezibalulekile okufanele uzikhumbule. Nakhu okufanele ukubheke ukuze uqiniseke ukuthi ubambisana nabahamba phambili.

1. Izinsiza Ezithuthukile Nobuchwepheshe

Ukuze ufinyelele izinga lokunemba okudingekayo, umphakeli wakho udinga ukuba nezinto zokusebenza ezisezingeni eliphezulu. Lokhu kufaka phakathi imishini yokugaya ye-CNC, izinsimbi ze-CNC, imishini ye-EDM yocingo, namanye amathuluzi anemba okuphezulu angafinyelela ukubekezelelana okuqinile kanye namajiyometri ayinkimbinkimbi.

●Imishini ye-CNC ye-Multi-axis:Imishini enama-ax angu-3, 4, noma angu-5 ivumela ingxenye eyinkimbinkimbi yejometri kanye nomsebenzi onembile. Lokhu kubaluleke kakhulu ezimbonini ezifana ne-aerospace noma ezokwelashwa, lapho imiklamo eyinkimbinkimbi iyinto evamile.

●Imishini ye-EDM yocingo:Le mishini ibalulekile ekusikeni izinto eziqinile kakhulu nokudala imininingwane eyinkimbinkimbi amathuluzi ajwayelekile okwenza imishini angakwazi ukuyiphatha.

Hlola amakhono omphakeli ukuze ubone ukuthi ahlonyiselwe yini ukuphatha inkimbinkimbi nokunemba okudingwa yizingxenye zakho.

2. Okuhlangenwe nakho Nobungcweti

Ukukhanda izingxenye ezinemba okuphezulu akuyona into engenziwa yiwo wonke umphakeli. Kudingeka isipiliyoni, ulwazi, nekhono ukukhiqiza izingxenye ngokungaguquguquki ekubekezeleni okuqinile okudingekayo ezimbonini ezifana ne-aerospace noma ukukhiqizwa kwezokwelapha.

Umphakeli onomlando oqinile namava embonini yakho uzokwazi:

● Qonda izinselele ezithile zohlelo lwakho lokusebenza.

● Nikeza izincomo zokuthuthukisa ingxenye yedizayini yakho ukuze yenzeke.

● Qinisekisa ukuthi izinqubo zabo zihambisana namazinga nemithetho yemboni (isb, izitifiketi ze-ISO, i-AS9100 ye-aerospace, noma ukuthobela kwe-FDA kwemishini yezokwelapha).

Kuhlale kuwumqondo omuhle ukucela izifundo zecala, ubufakazi, noma izinkomba zeklayenti ukukala izinga lobuchwepheshe bomphakeli kanye nekhono labo lokusingatha amaphrojekthi ayinkimbinkimbi.

3. Ukulawulwa Kwekhwalithi kanye Nezitifiketi

Ukulawulwa kwekhwalithi kubalulekile uma kuziwa ekwenzeni imishini enembayo ephezulu. Ngisho nokuchezuka okuncane ekubekezeleni kungase kubangele ingxenye engasebenziseki noma ehluleke ukuhlangabezana namazinga okuphepha. Bheka umphakeli onezimiso eziqinile zokulawula ikhwalithi, njengalezi:

●Isitifiketi se-ISO 9001:Leli zinga lomhlaba wonke liqinisekisa ukuthi umphakeli uzibophezele ekugcineni izinqubo zokuphatha ikhwalithi.

●Ukuhlola Kwangaphakathi:Buza ngamathuluzi nezinqubo umphakeli azisebenzisayo ukulinganisa nokuhlola izingxenye, njenge-CMM (Coordinate Measuring Machines) noma izikena ze-laser. Lawa mathuluzi angasiza ukuqinisekisa ukuthi izingxenye zihlangabezana nokucaciswa okunembile ngaphambi kokuthi zikhishwe.

Umphakeli omuhle uzokwazi futhi ukukunikeza imibiko yokuhlola kanye nemibhalo yeqoqo ngalinye lezingxenye abazikhiqizayo.

4. Isikhathi Sokushintsha kanye Nokwethenjwa Kokulethwa

Ekukhiqizeni, isikhathi siyimali. Ukukhetha umphakeli ongahlangabezana nezinsuku zakho eziwumnqamulajuqu kubaluleke njengokukhetha ongaletha izingxenye zekhwalithi ephezulu. Bheka umhlinzeki:

● Inerekhodi eliqinisekisiwe lokulethwa ngesikhathi.

● Inikeza ukuxhumana okucacile mayelana nezikhathi zokuhola nanoma yikuphi ukubambezeleka okungaba khona.

● Inekhono lokukala umkhiqizo uma kudingeka kuma-oda amakhulu noma imisebenzi eshintsha ngokushesha.

Abahlinzeki abanokugeleza komsebenzi okuzenzakalelayo kanye nezinhlelo zokuhlela ukukhiqiza eziqinile bavame ukwethembeka kakhulu ekuhlangabezaneni nezinsuku zokugcina futhi bazivumelanise nezinguquko ezifunwayo.

5. Ukuvumelana nezimo kanye nokwenza ngokwezifiso

Ukunemba okuphezulu kwezingxenye zemishini kuvame ukufaka izingxenye ezihlukile noma ezenziwe ngokwezifiso ezingakwazi ukukhiqizwa ngobuningi. Kungakhathaliseki ukuthi udinga ama-prototypes aphuma kanye noma ama-prototypes amancane kuya kwamaphakathi, kubalulekile ukusebenza nomphakeli oguquguqukayo futhi okwazi ukuzivumelanisa nezidingo zakho.

●Amakhono Okwenza i-Prototyping:Ingabe umphakeli angadala ama-prototypes ukuze ahlolwe futhi aqinisekiswe ngaphambi kokukhiqizwa okugcwele?

●Usizo Lokuklama:Ingabe banikeza usekelo lobunjiniyela ukuze ucwenge imiklamo yakho futhi uqinisekise ukuthi ithuthukiswe ukuze wenziwe?

Umhlinzeki ongasebenza nawe kuzo zonke izigaba—kusuka ekwakhiweni kuya ekukhiqizweni kokugcina—angenza umehluko omkhulu empumelelweni yephrojekthi yakho.

6. Amanani Wokuncintisana

Ukunemba okuphezulu kwemishini kungabiza ngenxa yemishini ekhethekile nobungcweti obudingekayo. Nakuba ungafuni ukuyekethisa kukhwalithi, kusabalulekile ukuthola umphakeli onikeza amanani ancintisanayo. Qiniseka ukuthi:

● Cela izingcaphuno ezicacile, ezinemininingwane ezichaza zonke izindleko ezihilelekile, okuhlanganisa ukusetha, ukwenza imishini, nokuqeda.

● Cabangela ubudlelwano besikhathi eside. Kwesinye isikhathi, ukuzibophezela kuma-oda amakhulu noma avelayo kungaholela ekwehleni kwentengo kanye nenani elingcono kakhulu.

Ungamane nje ufune inketho eshibhe kakhulu—bheka umhlinzeki olinganisa izindleko, ikhwalithi, nokwethembeka.

Ukukhetha umphakeli womshini wokunemba okuphezulu kuyisinqumo esibalulekile. Ungamane uthenge ngokusekelwe enanini eliphansi kakhulu. Hlanganyela nethimba elibonisa ubungcweti, okokusebenza, futhi—okubaluleke kakhulu—ukunaka kakhulu imininingwane edingwa yiphrojekthi yakho.

Ukuqamba kwakho okusha kudinga isisekelo esakhelwe ukuphelela.

Siyaziqhenya ngokubamba izitifiketi ezimbalwa zokukhiqiza zezinsizakalo zethu zemishini ze-CNC, ezibonisa ukuzibophezela kwethu kwikhwalithi nokwaneliseka kwamakhasimende.

1,I-ISO 13485: ISItifiketi SoHLELO LOKUPHATHWA KWAMADIVISI EMIDILI

2,I-ISO9001:UHLELO LOKUPHATHWA KWEQUALITY

3,IATF16949,AS9100,SGS,CE,I-CQC,I-RoHS

● I-CNCmachining enhle kakhulu ye-laser eqoshiwe engcono kakhulu ye-Ive everseensofar Ikhwalithi enhle iyonke, futhi zonke izingcezu zazipakishwe ngokucophelela.

● Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo Le nkampani yenza umsebenzi omuhle ngempela ngekhwalithi.

● Uma kunenkinga bayashesha ukuyilungisaUkuxhumana okuhle kakhulu kanye nezikhathi zokuphendula ngokushesha

Le nkampani ihlala yenza lokho engikucelayo.

● Baze bathole noma imaphi amaphutha okungenzeka ukuthi sesiwenzile.

● Sesisebenzelana nale nkampani iminyaka eminingana futhi besilokhu sihoxisa isevisi eyisibonelo.

● Ngijabule kakhulu ngekhwalithi evelele noma izingxenye zami ezintsha.I-pnce inokuncintisana kakhulu futhi isevisi yekhasimende iphakathi kwezingcono kakhulu engake ngaba nazo.

● Ikhwalithi esheshayo ye-tumaround, kanye nesevisi yamakhasimende ehamba phambili noma yikuphi emhlabeni.

Q:Ngingayithola ngokushesha kangakanani i-prototype ye-CNC?

A:Izikhathi zokuhola ziyahlukahluka kuye ngengxenye yobunkimbinkimbi, ukutholakala kwezinto ezibonakalayo, nezimfuneko zokuqeda, kodwa ngokuvamile:

●Ama-prototypes alula:1-3 izinsuku zebhizinisi

●Amaphrojekthi ayinkimbinkimbi noma anezingxenye eziningi:5-10 izinsuku zebhizinisi

Isevisi esheshayo ivame ukutholakala.

Q: Yimaphi amafayela okuklama okudingeka ngiwanikeze?

A:Ukuze uqalise, kufanele uthumele:

● Amafayela e-3D CAD (okungcono abe ku-STEP, IGES, noma ifomethi ye-STL)

● Imidwebo ye-2D (i-PDF noma i-DWG) uma ukubekezelela okuthile, izintambo, noma ukuqedwa kwendawo kuyadingeka

Q: Ungakwazi yini ukuphatha ukubekezelelana okuqinile?

A:Yebo. Imishini ye-CNC ilungele ukufeza ukubekezelelana okuqinile, ngokuvamile ngaphakathi:

●±0.005" (±0.127 mm) okujwayelekile

● Ukubekezelela okuqinile kuyatholakala uma ucelwa (isb, ±0.001" noma okungcono)

Q: Ingabe i-CNC prototyping ilungele ukuhlolwa okusebenzayo?

A:Yebo. Ama-prototypes e-CNC enziwe ngezinto zangempela zebanga lobunjiniyela, okuwenza alungele ukuhlolwa okusebenzayo, ukuhlolwa kokulingana, nokuhlolwa kwemishini.

Q: Ingabe unikeza ukukhiqizwa kwevolumu ephansi ngaphezu kwama-prototypes?

A:Yebo. Izinsizakalo eziningi ze-CNC zihlinzeka ngokukhiqizwa kwebhuloho noma ukukhiqizwa kwevolumu ephansi, ilungele amanani ukusuka ku-1 kuya kumayunithi angamakhulu amaningana.

Umbuzo:Ingabe umklamo wami uyimfihlo?

A:Yebo. Amasevisi ahloniphekile e-CNC ahlala esayina Izivumelwano Zokungadaluli (ama-NDA) futhi aphathe amafayela akho kanye nempahla esunguliwe ngobuhlakani obugcwele.